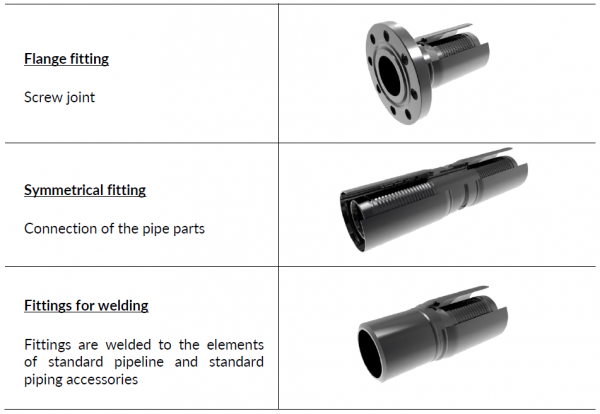

OILTECHPIPE flexible pipes are connected with metal pipes and various details using end fittings. Pipes are supplied with two kinds of end fittings: flange pipe fitting and the welded pipe fitting. Flexible pipes are interconnected by means of symmetric pipe fittings.

Types of fittings

It is possible to produce fittings according to the requirements of the customer. Fittings can be produced according to GOST, ANSI standards.

The fitting material is typically chosen based on the compatibility of the pumped liquids and corrosion characteristics of the material. Carbon steel is commonly used in cases where corrosion is not a major concern, for example, for testing flexible pipes of for dry gas transportation. It is recommended to use stainless steel fittings when transporting corrosive liquids.

Equipment for fitting mounting

A hydraulic press for crimp connection of fittings with flexible pipes in the field is designed for various types of fittings (Figures 1, 2). A hydraulic press is designed to work with flexible pipes with the inner diameter 2″ to 8″. A hydraulic press should be used together with a hydraulic station with the following parameters: working pressure – up to 3000 psi., a flow rate – 3 l/min, pressure regulation option for proper functioning.

The operating pressure of this unit ensuring the tightness of the fitting – flexible pipe connection reaches 3000 psi.

Figure 1 – Hydraulic press for installing pipe flange fittings and welded pipe fittings

Figure 2 – Hydraulic press for installing pipe symmetrical fitting and welded pipe flange fittings