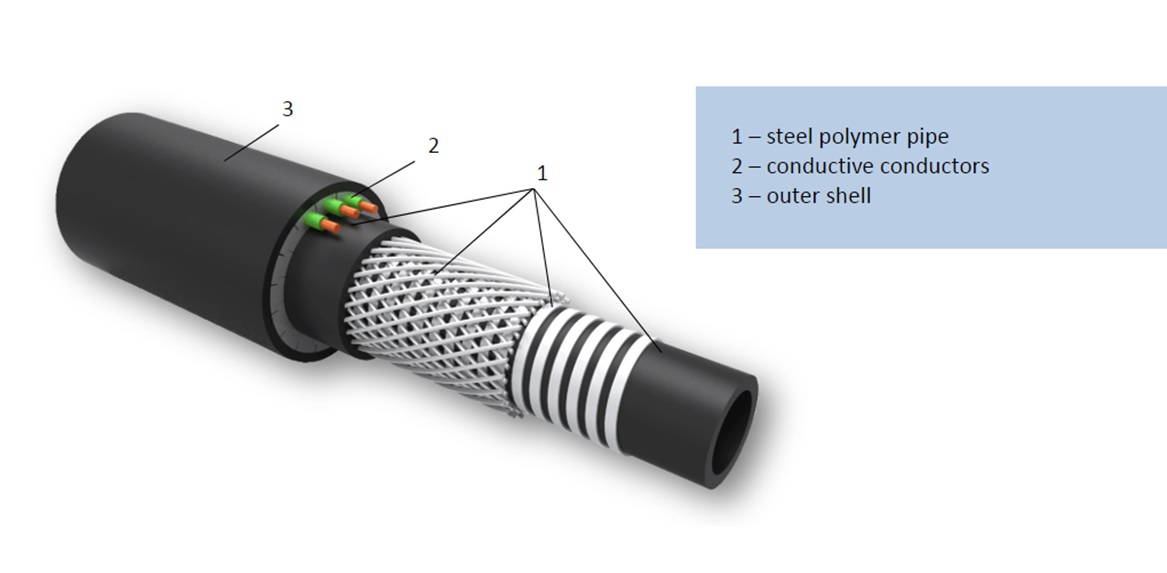

Umbilical construction

What are the advantages of umbilical cable over regular tubing string?

• Checking the tightness of the column is carried out at the factory.

• The time of work is sharply reduced, due to the exclusion of operations on twisting of NKT.

• The safety of the work is increased, since when the umbilical is launched, the personnel are not nearby, but only supervising the lowering process.

• Since the umbilical is made in one piece, there is no chance of leaks at the junction of two pipes.

• The probability of damage to the power cores is reduced, since they are located under a reinforcing sheath, which has excellent damping and protective properties.

• The environmental safety of the work increases since the wellhead is hermetically sealed during tripping, which eliminates the likelihood of a blowout or spill.

• On the inner surface of the pipe, the process of deposition of ARPD occurs much less intensively.

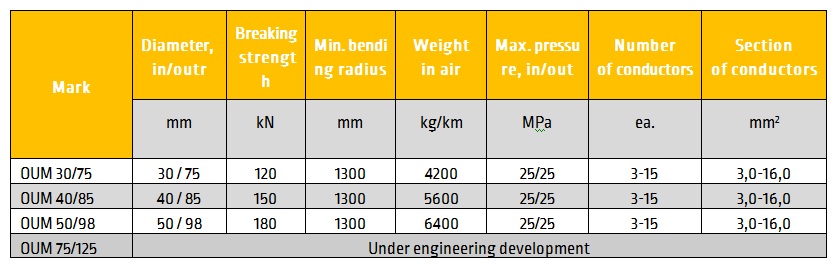

Table 1 – Technical parameters

Pipe corrosion resistance

Steel-polymer pipes have higher corrosion resistance. Polyethylene is a main material, which is used in the production of our pipe, has operational life of 50 years that is significantly more in comparison with standard structural steel which is used for tubing production. Besides, polyethylene is more resistant to the influence of aggressive environments such as hydrogen sulfide and carbon dioxide which can be present in a well.

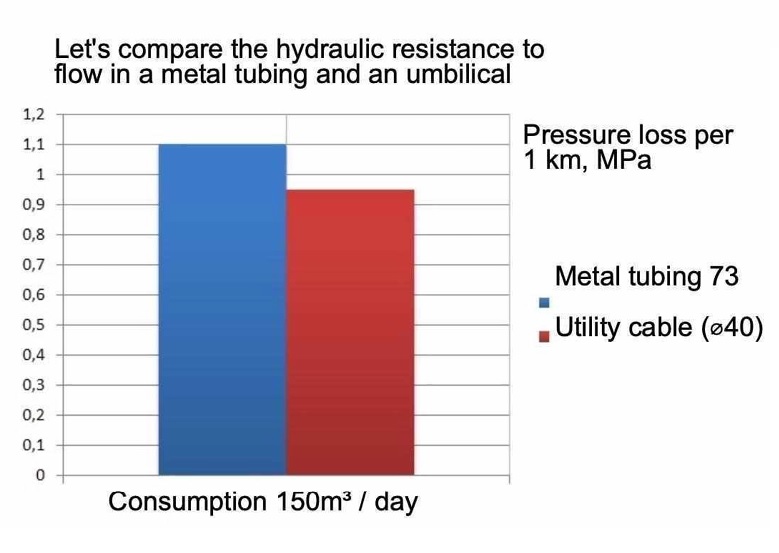

As a result, hydraulic fluid resistance in umbilical with inner diameter 40mm is in practice equal to the resistance of tubing string NKT 73.